What does it take to build a video card or a motherboard? ZOTAC was kind enough to take us through their factory to show how it is done. Read along as we discover how everything is assembled and qualified through stress tests.

A tour of Zotac’s Factory in Dongguan, china

PC Partner, manufacturer for ZOTAC and other major companies

In the previous years, Bjorn3D has been lucky enough to take part of several factory tours, including a Kingston factory tour in Hsinchu, Taiwan. Bjorn3D managed to take part of an even larger factory tour this year in Dongguan, China, at the PC Partner facility. PC Partner was established in 1997 and is one of the main providers of electronic manufacturing services (EMS), motherboards, graphics cards and other consumer electronics. With their ISO 9001 certification, PC Partner is committed to delivering products to the table with the quality required to meet international standards. ZOTAC, one of the leading innovators in mini-ITX motherboards and channel manufacturer is a proud subsidiary of PC Partner, one of the five giant contractors of the PC business. Though ZOTAC is not the only subsidiary of PC Partner, in this article, we’ll solely focus on how ZOTAC’s products are put together from the exposed Printed Circuit Boards (PCBs) to the finished working and packaged product.

Milton Fang explains ZOTAC’s background and their plans for the future.

Before we entered the factory floor, Director of Sales and Marketing, Milton Fang gave a presentation about ZOTAC’s current situation and their plans for the future. Milton explained, “ZOTAC is not just a fly by night marketing company that will fold and sell their names at any time.” Because of the scale of production and strategic partnership with larger corporations, including NVIDIA, Intel, AMD, VIA and others, ZOTAC can be considered as a good partner due to global manufacturing, financial and distributive reach. With the consistency and quality of PC Partner’s manufacturing, every batch of products must go through rigorous production and quality process and control. Milton continued by pointing out ZOTAC’s continuous growth in the industry, as they are becoming quite successful in Europe, and are continuously growing in India, China, Japan and Australia.

ZOTAC has only been in business for about 4 years now, and while they are still quite new to the computer industry, their plans are to provide professional customer service and warranty for their customers. At the moment, their customer service via phone is not accessible 24/7. ZOTAC’s plans are to provide 24/7 support via phone, chat, email and even text messaging to their customers as they continually grow in the industry. Though most of their products have a 3 year warranty, some products also receive a 5 year warranty in the US. They explained that they will try to work with their customers on getting them the services they need even if they have not registered their products within the 30 days, as required, though it is highly recommended for each customer to register their products to make sure they will not miss out on services in case problems arise.

While enjoying our two day vacation in Hong Kong and Dongguan, Senior Vice President of Latin American Sales John Engle explained, “Once you’ve seen an SMT line, you’ve seen them all.” We can certainly agree with this comment, as previous factory tours in Hsinchu, Taiwan; Fountain Valley, California; and Camarillo, California show the only difference between each surface-mount technology line is the product being built and the amount of time each product takes to put together from the PCB to the shipping box. Even though we might have seen previous SMT lines in the past, we highly encourage taking a look at ZOTAC’s SMT line as we take a look at what it takes to build video cards, and ZOTAC’s famous ZBOX mini-PCs.

Before any production begins, each PCB being used during manufacturing receives a bar code. This bar code serves as a checkpoint for the PCB to make sure it went through all the stations before it is packaged into the shipping box. Each board is examined for damaged parts and marked if there are any problems spotted. We can see a clear representation of this on the second picture where we see what looks like a PCB for two PCI-Express graphics cards still connected on a single PCB board.

After examination, each PCB board is placed into a rack which is fed into the main SMT line. Of the 45 SMT lines at PC Partner, about 10-15 are dedicated to ZOTAC. In the pictures we will be taking a look at only one SMT line. Keep in mind that with 10-15 SMT lines, the production rate increases and it is possible to produce up to two million units in a single month. The first machine the PCB gets fed into is the Solder Paste machine. A thin but wide soldering head moves down and applies a thin layer of solder paste across the PCB. Special cut out boards are used to make sure paste is only applied to areas of the PCB that need solder paste. We can see the PCB continuing down the line after a very thin layer of solder paste has already been applied to the contact points. At this point, the system automatically checks the barcode on the PCB to update its status.

After passing the PCB on to the next machine, extremely small components are laser mounted onto the PCB. At this point the components are not soldered to the PCB yet, but will be in the next process. Another machine picks up larger components and large machine arms quickly position components all over the PCB. Certain SMT lines have alignment machines that make sure each component is aligned correctly before the PCB continues on to the ovens; in this case, we did not see this. Because of this, additional human labor is required in the following steps to make sure each component is mounted properly onto the PCB.

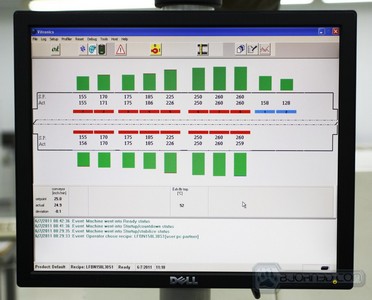

After most of the smaller components are placed onto the solder paste, the PCB moves through an oven for several minutes. The LCD monitor shows each part of the oven with different temperature settings. The oven helps solder the components onto the PCB. Towards the end the temperatures reach up to 260 degrees Celsius. Because this is just a short amount of time that the components heat up to these temperatures, there is no damage done to any of the electronic components. There is a quick cool down towards the end, however it is still dangerous to touch the heated PCB.

After the soldering process, several workers use sheets with cutouts to make sure all the components are correctly placed on the PCB. Another imaging machine creates a high-definition image of the recently soldered components to check for soldering problems, while the last 3D X-Ray machine checks for defective components. After the installation of the 3D X-Ray machine, the number of defective products dropped drastically. The machine is able to lower the defective parts margin drastically to only 100 defective parts per million.

The Factory Floor

The Lengthy Process of building Graphics Cards and Motherboards

Sometimes larger components like the memory chips, graphics processing units, capacitors and connectors cannot be easily put on by machines due to misalignment. We have noticed that the PC Partner factory was missing a machine that we have seen at other factories. Maybe we just missed it by accident, but this machine examines the PCB for misaligned components in case larger components are placed on the PCB by machines. It is likely that because this is not available at this factory, human labor is required in assembly line format to finish putting together the final product. However, it looks like the memory chips and GPU are already securely placed on the PCB, so it is likely we were just not taken through that process during the factory tour. Workers continue placing the DVI, HDMI, ferrite core chokes, capacitors, and other components onto the graphics card PCB. The first and second picture shows workers cutting apart each PCB into two separate pieces. After the cutting they swiped across a sandpaper to make sure the edges are not sharp. The last picture in the group of 4 pictures shows the soldering system which fills up the soldering holes in the PCB where the freshly put components and parts were placed.

After the cards go through the soldering system, they get checked by the workers. Additional solder is added if needed to make sure each component is soldered correctly only to PCB. After a quick cleaning of the PCB, the cards are placed in protective card board cases. These get stacked in shelves and later passed on to the next assembly line where additional parts are added to the cards.

The next step is to prepare the video card so they can be used without damaging any components. Workers continue adding PCI-Express slot brackets, nuts for monitor cable screws, heatsinks, and much more. Other works make sure the PCI-Express slot connectors are clean by cleaning them with alcohol. After the product goes through this line, the it is ready to be tested. We’ll take a look at testing and packaging on the next page.

Here we can see the testing facility for the video cards and other products, however, before we continue on to testing, we would like to explain the working conditions for these workers at PC Partner. With 10-15 SMT lines dedicated to ZOTAC, 6000 workers need to be available to work the lines. Without this workforce it would be impossible to put out two million units per month. Employees work for about 8 hours daily, however, they get 2 hours paid overtime. This means that some workers work up to 10-hour shifts six days a week. Average wages range at about 1800-2000 RMB, which equals roughly to about 300 US Dollars per month. Even though this sounds little to most US citizens, this wage is claimed to be competitive with other factories in the region. Employees also get dormitories right by the factory so they would have a place to live and get back to work when their shift starts. Even though this sounds a bit rough compared to different lifestyles around the world, there have not been any problems with the way things are run around the facility.

Besides the employees at the Dongguan factory, ZOTAC has a few other offices around China, one particularly in Hong Kong and Shen Zhen, China. There are over 230 R&D (research and development) engineers in house at these locations to keep the competition up between other vendors.

The ZBOX Line

The ZBOX SMT line is essentially the same as the graphics card SMT line, however instead of just putting together a video card, workers work in a line to put together a complete computer system. The system goes through rigorous tests and usually takes a bit longer to finalize than a video card. Lets take a look at testing and packaging on the next page.

Environmental Testing

Shock, Heat, Humidity, Performance and Stability Testing

The testing portion of the ZOTAC factory is definitely interesting. The first picture shows the so called “secret” performance testing room, where workers essentially play games throughout the day to make sure everything works the way they should when the end-user receives their product. The 2nd picture shows a specific LCD test being run on a freshly assembled video card. Some of the other tests performed in this process consist of VGA 2D tests, video playback, Windows-based tests, as well as 3D testing with Futuremark products. If the products pass all the tests, they are sent to the next assembly line where they are packaged for release.

There are special tests performed before any product is put out on the market from ZOTAC. As far as we know, only select cards are tested in the following environments, but that’s to make sure that the retail products can withstand the different environmental differences when users receive their products. The 4-Corner Test runs each component through various voltage and temperature tests to make sure that the product will run stable during these stress tests. The Motherboard Real-Time Clock Precision Evaluation puts a motherboard in a 40C environment for 168 hours. After the test, the machine records the contrast between CMOS clock and standard clock. The Vibration Test pushes the computer components to their limit by measuring how much vibration each component can withstand. This is to simulate case vibration caused by computer fans and moving components inside the system.

The next machine (labeled TERCHY) name performs a 5 year accelerated life test on the computer hardware in less than a week. This simulation is calculated with a simple yet complicated formula. Using this formula, the machine tests how adjusting the temperature and humidity of the environment can drastically effect the lifespan of the hardware. With this, it is possible to simulate several years of operation within a few days. In this case, the incubator is set to run at 85 degrees Celsius and at a 85% humidity for six days.

The next environment test is performed at the given temperatures and humidity settings ranging from -40C to 85C and from 10% to 95% humidity environments. Finally there is a thermal shock test which, depending on the product, will ramp the temperature up and down to extreme levels. For example, motherboards go all the way up to 125C or all the way down to -55C.

Motherboard and ZBOX products go through rigorous tests including all the I/O ports and motherboard slots which can be utilized by the end-user. If the product fails at any of the steps, the product will go back to the repair section where workers try to figure out where the problem might be. If the problem is found and can be easily fixed, the product is fixed and sent through testing again to make sure everything is working properly.

Packaging and Shipping

After the products have passed all the tests, they are sent to packaging. In these images we can see the GTX 520 passively cooled video card being packaged. Before it gets put into the packaging with the rest of the accessories and user manuals, the card is finally checked by the bar code reader to finalize the process. After that the bar code is ripped off from the PCB, and the card is handed on to the workers packaging the product.

The same process is done with the ZBOX and motherboards that ZOTAC sells. After the products pass the tests, they get checked off, and packaged into the retail packaging. These retail boxes are placed into another box that get shipped off to distributors and large stores.

We hope you’ve enjoyed reading about our ZOTAC factory tour. It is definitely an interesting place, and there’s a lot to see. Stay tuned with us for new reviews every week.

Bjorn3D.com Bjorn3d.com – Satisfying Your Daily Tech Cravings Since 1996

Bjorn3D.com Bjorn3d.com – Satisfying Your Daily Tech Cravings Since 1996

Thank you. You did a great job!