SilverStone Tundra TD02-E A Closer Look

We thought it would be interesting to picture the Tundra Series side by side, and you can tell they are born of the same lineage. Both units share the same tubing, fans and pumps and while they both have two fans, the TD02-E has double the radiator surface area. While the Tundra TD02-E has two fans like its little brother, the increased surface area of the radiator will offer better cooling.

With two fans attached, you’re looking at 57mm of needed clearance in your chassis with a dual radiator mountable site. Slap a couple more fans on the Tundra TD02-E and you’re looking at a thickness of 82mm. If you do use extra fans on a radiator they should be the same model, speed and CFM to get the best possible airflow. In a push or pull configuration, what you’re really looking at is the fans pushing the air through the radiator and meeting heat sink fin resistance, which slows the airflow down. This can be handled by adding two more fans in a push/pull-configuration, where the added fans speed up the air again. In our experience the two extra fans will only gain you a nominal thermal advantage.

Almost understated in its appearance, you would hardly notice the SilverStone Tundra TD02-E if it weren’t for the two 120mm fans with white blades. SilverStone has a long-standing tradition of understated equipment, often preferring matte black over other flashier choices. From the Raven chassis to their world-renowned power supplies, SilverStone has produced matte finish products that extrude quality but don’t detract from the highlighted portions of your dream rig.

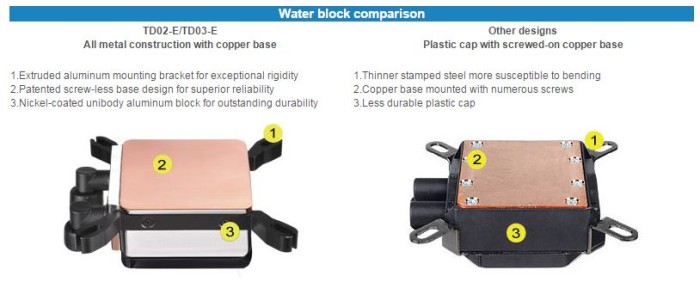

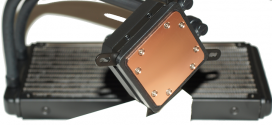

The CPU water block on the Tundra TD02-E shows a few milling marks to the naked eye, but running your fingers across it will tell you that it’s smooth (and that you need to wipe those finger prints off). Those clips on the edges of the block are substantial aircraft grade aluminum and some of the most solid hold down clips we have ever seen. The body of the water block is nickel plated extruded aluminum and the contact surface is of course copper. If the image has been bugging you it’s probably because the water block CPU contact surface has no screws. Screws have a different density and thermal properties than copper and because of their durability needs, are a harder and less conductive material. Toss six or eight screws on the surface of this block and you just killed some of its thermal conductivity. Leave it to SilverStone to revolutionize a screw-less CPU block contact surface.

1. The SilverStone TD02-E had solid aluminum (substantial) mounting brackets that we can only describe as Military grade (or above), while other solutions we have seen only offer flimsy, stamped steel hold downs. Normally, the flimsy, stamped steel hold downs come in three or four different configurations for different CPU sockets and merely sit on top the block and bend easily. Easily bent hold downs mean worse performance from a block that’s not held down uniformly.

2. The SilverStone Tundra TD02-E has a solid, unbroken brass CPU contact surface while every other solution we’ve seen has a multitude of screws holding the block together. Those screws aren’t made of copper and don’t conduct heat as well as copper, so you’re losing efficiency for every screw on the copper surface.

3. The SilverStone Tundra TD02-E sports a nickel-coated aluminum unibody, as opposed to a plastic body that can be found on most other liquid cooling solutions. We much prefer the nickel-coated aluminum. Not only is it more durable, but plastic is a horrible thermal conductor. The nickel-coated aluminum body of the block contributes to its over all efficiency.

Like any other product, the devil is often found in the small, overlooked details. Where other companies have decided to maximize profit and use stamped steel and plastic, SilverStone has decided to use copper nickel and aluminum. It’s not really a hard choice here: State-of-the-art, metal all-in-one that maximizes heat transfer, or plastic that maximizes profit. It’s not hard to tell a company that takes more pride in its product that it does in its profit.

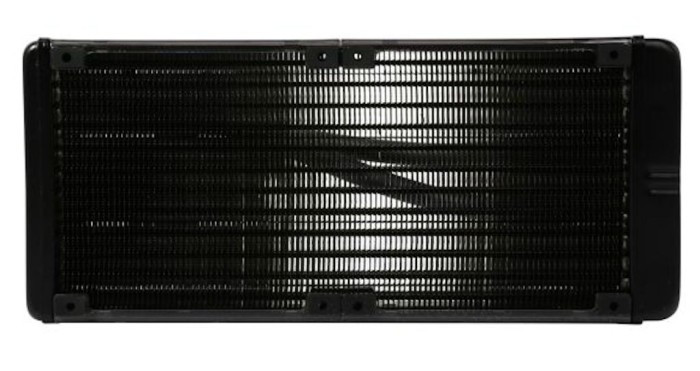

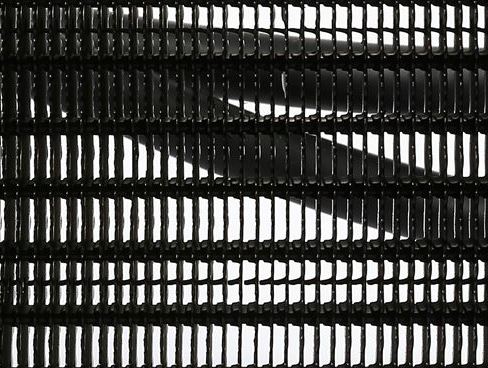

The dual radiator uses patented, brazed heat sink fins that have more contact points than traditional PC radiators.

Notice in this close-up that both sides of the heat sink fins touch the coolant tubes, and as you will see in a second, that’s a lot more contact than traditional radiators.

The SilverStone Tundra TD02-E design (left image) shows the premium, soldered heat sink array. Notice how open of a design it is and it makes full contact on both sides. On the traditional design, two legs on one side and one on the other contact the coolant tubes. It’s fairly obvious the SilverStone Tundra TD02-E radiator will also allow more air flow with less resistance; more air flow = more heat removed. Using this design, SilverStone claims up to 40% more cooling efficiency.

Here’s a shot of one of the APA1225M12 DC (AP12 25mm 12V DC) fans. The leading edge of the fan is notched and the rear edge has a groove running along the length of the blade. We could venture a well-educated guess that the notched edge and the groove break up the air just enough to keep the fans from making too much noise, as these beauties purr along at (Maximum) 35dBA. For those that don’t speak dBA, that’s about the level of noise in a quiet library. Our test rig is located about two feet in front of us, and with the SilverStone Raven buttoned up, you can’t hear the fans, even when the system is under full load CPU testing.

Here’s a closeup of the fan’s model number. While SilverStone has an AP series of fans, they don’t list an AP12 with a white, flower-like blade. This may be a glimpse at a new addition to the SilverStone fan family.

Bjorn3D.com Bjorn3d.com – Satisfying Your Daily Tech Cravings Since 1996

Bjorn3D.com Bjorn3d.com – Satisfying Your Daily Tech Cravings Since 1996