Six enter the ring only one will leave. No holds barred thermal paste shootout, old school style. Let’s see if these so called contenders can beat the heat.

INTRODUCTION

Advances have been made in many fields of computer technology from displays to video cards and hard drive capacities to thermal pastes. So it shouldn’t come as a surprise that no self-respecting enthusiast would ever be caught using generic white paste to help cool their expensive computer equipment. Thermal interface material or TIM is something that anyone with a bit of patience and a few dollars can use to help lower the temperatures of their computer’s CPU, video card and even their Northbridge. Back in the day it was perfectly acceptable to use the included white paste that came with heatsinks as the heat output of PC’s was much lower than it is today. With ever increasing energy requirements it quickly became apparent that this generic goop just wasn’t going to cut it anymore. Company after company began developing the next best thing since sliced bread to help aid in heat transfer. With so many different options available from silver particles to diamond dust it is easy to become overwhelmed in a sea of paste. So let us do the work for you. Come with me as I put some of today’s most popular TIMs along with the timeless classics to the test against the white goo to see just how much of a difference it can really make.

The contestants

Thermodynamics 101

Before we begin testing I feel it is important to understand why these materials even exist today. In a perfect world flat would mean just that; flat. Take two flat pieces and push them together for a perfect bond. The problem is that there is no such thing as perfectly flat, only ‘flat enough’ for whatever your purpose is. Take any heatsink and place it under a microscope and you will see great ridges and valleys that you never knew were there. But that doesn’t explain why we need these pastes.

Air is an extremely poor conductor of heat. This has been known for quite some time in the housing industry which is where we get double-paned windows from. In between those two panes of glass is a space of air. When it is cold outside and you have the heat on inside, that space of air helps to keep the cold out and heat in. The inverse of this works in the summer when it is warm outside and you have the AC on inside. With so many ridges and spaces on that ‘flat’ heatsink of yours there are enough places for air to get trapped that would prevent the transfer of heat from your CPU. This is why we need these pastes. While they do not have the same level of heat conductance as metals used in heatsinks, they are far superior to air. From here they all differ in their chemical composition with some using particles of silver while others use diamond dust for its extremely high conductive properties. Still with me? Good, let’s get started.

TEST SETUP

All thermal pastes will be tested on both the CPU and GPU. The motherboard will be outside of the case and the temperature of the room was maintained at 24.5C -/+ 0.5C. The CPU will be cooled with an unmodified Thermaltake Big Typhoon while the GPU will have the Zalman VF900-CU.

| Test Platform | |

| Processor | Intel Core 2 Duo E6420 @ 2.1 GHz & 3.4 GHz |

| Motherboard | XFX 650i Ultra |

| Memory | 2 GB (2 x 1 GB) of G.Skill DDR2-800 |

| Drive(s) | 1 – Seagate 7200.9 Barracuda SATA 1 – Samsung HD501LJ SATA |

| Graphics | Albatron 8600GTS @ 675/1000 MHz & 720/1150 MHz |

| Sound | Creative Soundblaster Audigy2 ZS |

| Thermal Paste | T.I.M. 1 – Arctic Cooling MX-2 T.I.M. 2 – Arctic Silver Ceramique T.I.M. 3 – Arctic Silver 5 T.I.M. 4 – Zalman ZM-STG1 T.I.M. 5 – Thermalright Chillfactor T.I.M. 6 – IC Diamond 7 Carat |

| Cooling | CPU – Thermaltake Big Typhoon GPU – Zalman VF900-CU |

| Power Supply | OCZ GameXStream 850 watts |

| Display | Westinghouse 37″ LVM-37W3 |

| Case | Outside case |

| OS | Windows XP Pro SP2 |

Measurements

Temps are recorded for each paste at the following interval.

- 5 minutes

- 24 hours (1 day)

- 72 hours (3 days)

- 120 hours (5 days)

During this time both CPU and GPU intensive application will be run to aid in any curing that may be required. These applications include, but are not limited to, Folding@Home, Prime95 and gaming. After the five day break-in period the final readings will be taken for both idle and load temperatures. At this point I will overclock the CPU and video card separately to push the limits of each thermal paste as far as possible and record the idle and load temps at these new speeds.

Besides testing for the best temperature drop, we will also pay particular attention to the ease of application, fastest curing time and price-performance ratio.

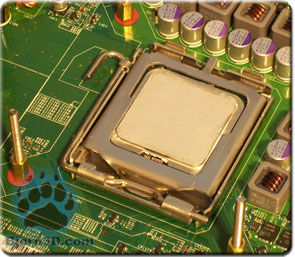

Thermal Paste Application

After testing a compound, the heatsink and die will be thoroughly cleaned with ArtiClean to remove all traces of compound before applying the new paste. Application of thermal paste will follow the manufactures instructions were applicable. Should no instructions exist then a thin layer of compound will be spread across the die using a plastic razor until it is covered from edge to edge.

Arctic Cooling: The company

ARCTIC COOLING is a private owned company founded in 2001 with headquarters in Switzerland, offices in Hong Kong and with production facilities in Asia. The team of ARCTIC COOLING insists on international young highly educated people with business, technical and communicational skills. The attitude to work is based on the Swiss innovative spirit and adheres to the high Swiss standard recognized internationally. This striving for excellence is integrated in all processes and is a matter of course.

MX-2

Turbo MX-2 is a high conductive and low resistance compound for components that require the best thermal dissipation. MX-2 is ideally suited for use in CPU, GPU cooling and other applications between power semiconductor components and heat sinks where high thermal conductivity is critical.

Arctic Cooling MX-2 package front and rear

(Click to enlarge)

Features

- High Thermal Conductivity

- Low Thermal Resistance

- Non-Electrical Conductive

- Non-Capacitive

- Non-Curing

- Non-Corrosive

- No Bleeding

- Odorless

Specifications

- Density: 3.69 g/cm3

- Viscosity: 2850 poise

- Net Weight: 4 g

No Metal Particles Since the MX-2 compound does not contain any metal particles, there are no problems regarding electrical conductivity and capacitance. In contrast to silver and copper compounds, contact with electrical traces, pins, and leads cannot result in any damage.

Durability: Arctic cooling states that curing and bleeding of the compound is not possible. In contrast to metal or silicon pastes, this compound does not show decreasing performance over time, does not need to be reapplied and has a durability of at least 8 years. This is a feature that caught my eye immediately. I had one of those ‘they started testing this in 1999?’ moments. Certainly anyone in the market for quality paste is going to change their paste more often then every eight years as the rule of thumb is once per year.

Left – MX-2 on a CPU. Right – MX-2 on a GPU.

(Click to enlarge)

Applying the compound: MX-2 is thinner then other compounds such as Ceramique. It spread very easily using a plastic razor and thankfully it is rated as electrically non-conductive as I would be nervous having such a thin compound leaking onto my motherboard. My own personal stereotype is that a thinner compound would more easily slip into the microscopic crevices of a heatsink and gain an advantage is cooling. We will see if this is fact or just a myth in just a bit.

Removing the compound: MX-2 being thin makes it much easier to remove than the thicker compounds. Using 90% isopropyl alcohol, the compound came right off and left very little residue behind for further cleaning.

Arctic Silver: The Company

Arctic Silver is a company many of us are familiar with. They are the de facto standard by which all other pastes are judged. They have been creating thermal compounds for a very long time and have always excelled at delivering a quality product. Here is a quote from their site:

Arctic Silver, Inc. is the premier manufacturer of high-performance thermally conductive compounds and adhesives for modern computers and other high-power electronics.

Ceramique

From the website of Arctic Silver

The high-density, ceramic-based thermal compound specifically designed for modern high-power CPUs and high-performance heatsinks or water-cooling solutions. The Evolution of Cool!

Features

- High-Density ceramic content

- Controlled Triple-Phase Viscosity

- Excellent Stability

- Electrical Insulator

- Easy Clean Up

- RoHS Compliant

Specifications

- Thermal Resistance: <0.007°C-in2/Watt (0.001 inch layer)

- Thermal Conductance: >200,000W/m2.°C (0.001 inch layer)

- Temperature limits: Peak: –150°C to >180°C Long-Term: –150°C to 125°C

Left – Ceramique on a CPU. Right – Ceramique on a GPU.

(Click to enlarge)

Applying the compound: Ceramique is a thicker compound than most and as such is a bit harder to spread. I should explain when I say it’s harder that it is only slightly so. I only applied the compound fully on the video card as the installation instructions found HERE direct you to apply it in a straight line according to the type of CPU you have.

Removing the compound: Since Ceramique is thicker in its makeup it takes a bit longer to remove then thinner compounds. It was not the hardest compound to remove but getting this stuff on my skin was no easy task to remove. Using the ArtiClean it removed all traces of the compound.

Arctic Silver: The Company

Arctic Silver is a company many of us are familiar with. They are the de facto standard by which all other pastes are judged. They have been creating thermal compounds for a very long time and have always excelled at delivering a quality product. Here is a quote from their site:

Arctic Silver, Inc. is the premier manufacturer of high-performance thermally conductive compounds and adhesives for modern computers and other high-power electronics.

Arctic Silver 5

From the website of Arctic Silver

Introducing Arctic Silver 5 With its unique high-density filling of micronized silver and enhanced thermally conductive ceramic particles, Arctic Silver 5 provides a new level of performance and stability. Now available at Arctic Silver dealers worldwide, Arctic Silver 5 is definitely The New Reference.

Features

- High-Density ceramic content

- Controlled Triple-Phase Viscosity

- Excellent Stability

- Electrical Insulator

- Easy Clean Up

- RoHS Compliant

Specifications

- Thermal Resistance:

- Thermal Conductance: >200,000W/m2.°C (0.001 inch layer)

- Temperature limits: Peak: 150°C to >180°C Long-Term: 150°C to 125°C

Left – A.S. 5 on a CPU. Right – A.S. 5 on a GPU.

(Click to enlarge)

Applying the compound: Arctic Silver 5 is easy enough to apply that you shouldn’t worry about making a mess. I only applied the compound fully on the video card as the installation instructions found HERE direct you to apply it in a straight line according to the type of CPU you have.

Removing the compound: Using ArctiClean removed the compound straight away with no fuss. This was expected since it is made by the same company who produces the cleaner we are using here.

Zalman: The Company

Known as a company determined to provide the best cooling products with the quietest noise levels it should come as no surprise that Zalman also offers their very own thermal compound. It will be interesting to see if being masters of mechanical design influences their ability to be crafty chemists.

ZM-STG1

Utilizing a novel method for applying the compound the ZM-STG1 looks to remove the inconsistencies that arise when applying thermal pastes.

ZM-STG1 (not shown to scale)

ZM-STG1 package front

ZM-STG1 package rear

Features

- Best Performance

- Ease of use

- Easy Storage

Specifications

- Temperature Stability: -40°C-150°C (-40°F-302°F)

- Capacity: 3.5 g

- Specific Gravity: 2.42

It is important to take note of the temperature stability listed by Zalman for this product. While -40°C is colder than many of us will see if you are using phase change or strong thermoelectric cooling this thermal paste may not stand up to the stress.

Left – ZM-STG1 on a CPU. Right – ZM-STG1 on a GPU.

(Click to enlarge)

Applying the compound: STG1 is probably the easiest compound to apply thanks to its clever brush system. Not unlike the applicator for nail polish, the STG1 uses a small brush to provide a thin even stream of compound to ensure maximum performance. The instructions on the box call for application on both the heat source (CPU/GPU) and the heatsink. Besides its innovative method for installation, STG1 is thinner compound and spreads very easily. It is not as thin as A.S. 5 so there is little fear of it running onto the surround PCB.

Removing the compound: Since STG1 is thin it is relatively easy to remove. Using the Arctic cleaning system the paste comes right off with no residue left behind.

Thermalright: The Company

Thermalright is known throughout the community as offering the very best in CPU and chipset coolers. Enjoying great success in the last ten years they did not sit on their laurels but rather came out with a CPU cooler so extreme it rivals some water cooling kits. To complete the cooling circle Thermalright designed the Chillfactor, a compound engineered to offer the very best in heat transfer. A quick trip to their new site reveals some odd information. Under the ‘about us’ heading found within the ‘contact’ tab has this information:

In our effort to consistently develop the very best and most innovative products, to meet and surpass our customer’s needs, ThermalRight must vigorously protect our company’s “Intellectual Property Rights”. To this end, the following “Product Admonishment” has been drafted by our Corporate Council and serves as a notice of information regarding our (ThermalRight, Inc.’s), Resolve in protecting said rights.

WARNING: All of the design elements of this and all ThermalRight products are the legally protected Intellectual Property of Thermalright, Inc. and. Any counterfeit copy, imitation, re-c, duplication, or sale and/or distribution thereof will constitute a direct violation of protected International Patents, Copyrights and Licensing Agreements and will subject any individual and/or entities imitating the design and/or selling, distributing, counterfeiting imitations or recreations to monetary damages.

The monetary damages include but are not limited to Fines, Penalties and Attorney’s Fees plus Injunctive Relief for each violation.

Surely there is more to this company than lawsuits to define who they are?

All joking aside Thermalright is a top-notch companies that makes some of the very best cooling products available.

Chillfactor

Thermalright Chillfactor package front and rear

(Click to enlarge)

Features

- Non-electrical conductive

- Easy application

- Easy to clean

- No health hazardous chemical

- Non-Curing

- Non-Corrosive

- No Bleeding

- Odorless

Specifications

- Volume: 4.8 ml

- Thermal impedance: 0.047

- Life expectancy after use: 12 months

Left – Chillfactor on a CPU. Right – Chillfactor on a GPU.

(Click to enlarge)

Applying the compound: When I first tried to apply the compound it came out of the tube as a liquid similar to the water that comes out of a ketchup bottle. As almost completely a liquid with very little consistency to it I was concerned first for my components and secondly if I was missing something. Neither the tub nor the packaging gave any indication of what to do so I proceeded to shake the tube in hope of “mixing” the compound. This did the trick as the paste was now coming out in a spread more like you would expect. Once ready it spread easily as it was still on the thin side of compounds.

Edit: It seems according to the new Thermalright web site that you are in fact SUPPOSED to shake the bottle before each use.

Removing the compound: Chillfactor being thin makes it much easier to remove than the thicker compounds. Using ArctiClean, the compound came right off and left very little residue behind for further cleaning.

Innovation Cooling: The Company

New to the scene of thermal compounds is a company called Innovation Cooling. Using a material unheard of in the world of computers, diamonds, Innovation Cooling hopes to market a thermal paste that offers performance greater than any other paste available today. A quick trip to their site offers us this insight into their mission:

Innovation Cooling LLC is a product development company specializing in applying advance technologies to electronic component cooling for a better, more cost-effective cooling solution than currently available. Our Mission is to provide our customers with advanced, proven high reliability technology cooling products for extreme performance. We use advanced technologies to deliver more cost-effective cooling solutions than are currently available – we do not market advanced technology products at inflated prices.

Diamond 7 Carat

Some PR quotes from heatsinkfactory.com

IC Diamond 7 Carat Thermal Compound maximizes thermal heat transfer between the CPU core and heatsink by taking advantage of diamonds superior thermal conductivity. Purified synthetic diamond has a thermal conductivity of 2,000-2,500 W/mK compared to 406-429 W/mK for pure silver. Diamonds five times better thermal conductivity compared to silver makes it a superior heat transfer material for cooling high performance CPUs and is electrically non-conductive and non-capacitive.

Features

- Non capacitive or electrically conductive

- Tight particle distributions

- Lower viscosity

- No health hazardous chemical

- Silicone free

- Non-Corrosive

- Odorless

Specifications

- Volume: 1.5g

- Thermal Conductance: 4.5 W/m-K

- Thermal Resistance: 0.25C-cm2/W@ 100 ì BLT

Left – Diamond Carat 7 on a CPU. Right – Diamond Carat 7 on a GPU.

(Click to enlarge)

Applying the compound: This is by the far the thickest compound I have ever encountered. It was so thick it quickly became apparent to me that spreading it was not going to happen. I would have to resort to the pea drop method for both the CPU and GPU. I placed a small drop of paste in the middle of the die and installed the heatsink. After a few minutes I removed the heatsink to ensure it had spread evenly throughout the chip. Once satisfied with the results I began testing.

Removing the compound: Removing the compound was like trying to wrestle a steak out of the mouth of a hungry dog. It just wouldn’t let go and it would take A LOT of wiping with ArctiClean to remove it (The paste not the dog). After removing the compound I spent five full minutes letting ArctiClean soak on the chip to ensure no residue was left behind. It was long and arduous and would not like to do that again.

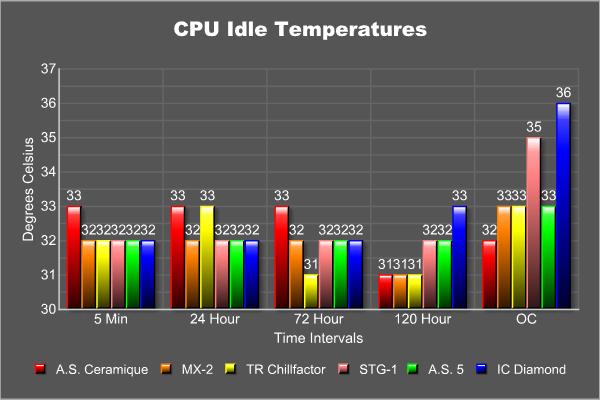

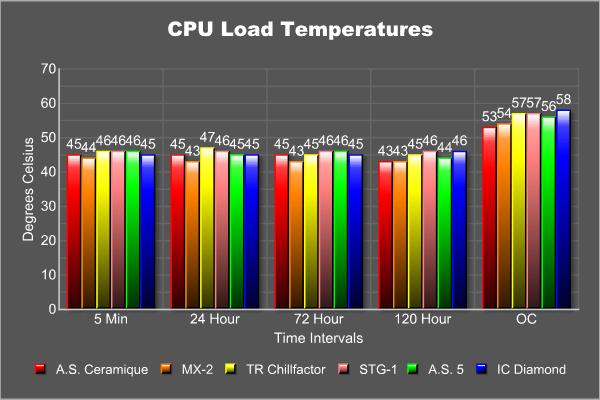

TEST RESULTS – CPU

I won’t bore you with a lot of speech here. The results speak for themselves. Just remember these charts do not start at zero and we have zoomed in so that you can more easily see the differences between the pastes. Before we show you the scores with the paste I wanted to show you just what would happen if NO paste was used.

| Temps | ||

| IDLE | LOAD | |

| CPU | 36 | 61 |

This was with an aftermarket cooler AND fan so to hit 61C at load is appalling. Of note, this was the score at stock speeds! I dare not to OC the CPU with no paste as we would easily hit over 75C and that’s just dangerous.

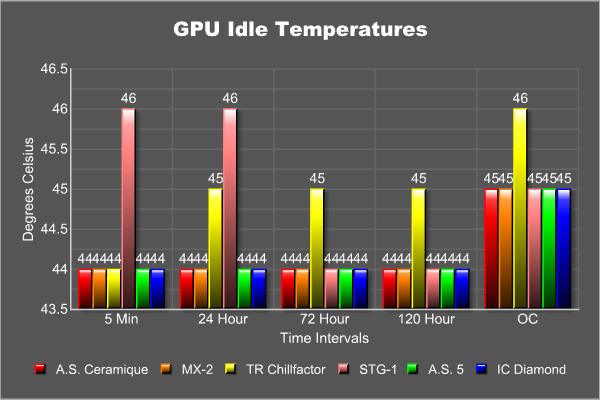

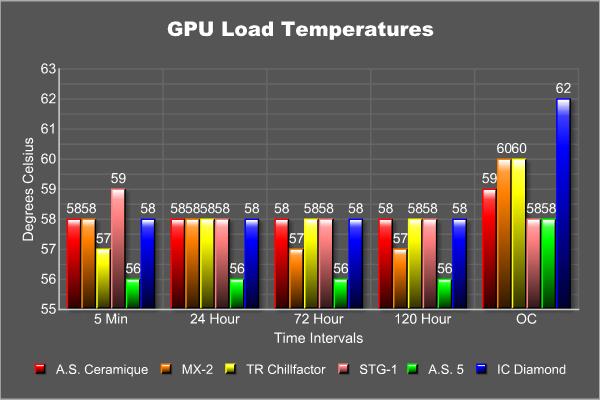

TEST RESULTS – VGA

CONCLUSION

So we saw a lot of pastes, we ran some tests and we had some fun but did we learn anything and is there a clear winner? Well first and foremost it should be clear that without any paste between the heat source and the heatsink there just isn’t enough contact between the two surfaces to properly transfer heat. All the of the compounds tested here performed admirable and you would do well to select ANY of these pastes over generic stuff.

Well lets hand out some awards shall we?

The winner of the ‘Easiest to apply’ award goes to: Zalman ZM-STG1!

By far this is the easiest to apply as it not only comes with a very handy applicator, the paste itself is not too thick and certainly not too thin so as not to run. I could only wish all thermal compounds were this easy to apply. If you find yourself always swapping out heatsinks or changing parts then this is the paste for you. Well done Zalman.

The winner of the ‘Fastest cure time’ award goes to: Arctic Cooling MX-2!

This was a tough award to assign as any of the competitors did very well. Taking into account both the CPU and VGA scores the MX-2 compound was able to eek out a win over the veritable ZM-STG1 in the area. If you can’t be bothered waiting for a compound to cure so you can test that massive overclock for stability than MX-2 is the compound of choice.

The winner of the ‘Best Thermal Transfer’ award goes to: Arctic Silver Ceramique and Arctic Silver 5!

Truly a killer one two punch. Neither compound was able to secure a victory on both fronts but with Ceramique taking the top spot in the CPU category and Arctic Silver 5 bringing home the gold for GPU’s it is a great day for Arctic Silver.

Well there you have it folks. No matter what your needs are there is a thermal compound to fit them. I hope you enjoyed reading this article as much as I did creating it.

Bjorn3D.com Bjorn3d.com – Satisfying Your Daily Tech Cravings Since 1996

Bjorn3D.com Bjorn3d.com – Satisfying Your Daily Tech Cravings Since 1996