While there were quite a few Kingston products announced during Computex, we were lucky enough to attend a meeting with David Sun, co-founder of Kingston, as well as take a tour and show you how all of our every day used memory modules are made at the Kingston Hsinchu Factory.

Meeting with Kingston and David Sun

On June 3rd, 2010, Bjorn3D and others were invited by Kingston to attend a meeting with David Sun, co-founder of Kingston Technology. This meeting was made possible to let us know about the latest products and advancements in the memory industry which we were able to already cover roughly 3 weeks ago. This also let us understand how the future for the memory industry will be shaped and get to know the story behind Kingston and how they became one of the major leaders in the memory industry. If you did not get a chance to take a look at Kingston’s latest products of 2010, please read our article HERE.

|

At the beginning of the meeting, David Sun introduced himself and jumped straight to questions to allow us reviewers and journalists ask questions that we would be interested hearing about. One of the first questions by one of the reviewers wondered how the recent drop in the economy effected Kingston in their product strategies. “Product Strategy, will keep going, regardless of the economy,” David Sun explained. He continued explaining that while other companies might get effected by the “roller coaster” economy, Kingston is not one of them. While other companies might drop in sales, Kingston continues to rise. This proved to be true when we compared Kingston’s annul revenue and how their overall revenue quadrupled in the last 9 years. In 2001, Kingston’s revenue was about 1,000 Millions of US Dollars, while in 2009, their revenue was around 4,100 Million, surpassing their 4,000 Million in 2008. This not only shows that Kingston is financially secured, but also that they know what they are doing. Keeping up with the latest technologies and providing the latest to their customers surely shows their success. |

The next question addressed to David asked about the DRAM market, wondering if Kingston is noticing any shrinking of the DRAM market as new hand-held devices and other such products start to become part of our everyday life. David has a very interesting stand on this issue. While from some sources we always hear that smart phones and other hand-held devices might take over the Desktop or Notebook PCs eventually, David still believes, that even though the there will be competition from devices like these, “the DRAM industry itself is going to be very good.” He continued to explain that even with new smart phones coming out, the computer systems will continue to grow, and the DRAM market will grow exponentially as well. He added that he believes that the smart phones will grow more as the years pass, but so will the speed of the processors, the use and capacity of the memories, and other internal devices in the phones, which is why he is not too much worried about the whole DRAM market. So to sum it all up, at the moment it seems that there is no shrinking in the DRAM market, but more like a growth. At the moment, even though you have a smart phone, you will still rely on a PC. Same goes with Home Entertainment. More people are moving to HTPCs than ever before, and there is a future in that as well. David believes, that even in the future, the smart phones might get more popular and better, but there will be certain things that you will still need a PC for.

Darwin Chen, Vice President of Sales and Marketing further added that David is not trying to imply that the PC industry and the DRAM manufacturing is shrinking, but that other devices like the smart phones have a much larger market share than before. It used to be that PCs market share was close to 100%, but now it is much lower because of other devices that are entering the market. The DRAM is still as widely used as before.

the truth behind Kingston

| The story behind Kingston and how they became so large throughout the years has truly shocked most of us at the meeting. Sure there was a lot of hard work involved during the past 25 years, and sure there were a lot of difficulties as well, but when David told us that the reason why Kingston is so big at the moment was because of “pure luck”, it became ten times more interesting. It was not just one big luck that brought him to this possition, but many good lucks over the years. You could say that Kingston got so lucky as comparing you to having a really large chance of winning the lottery.

Kingston got started in 1985. An engineer called David up, wondering why a memory module costs $200 compared to another company that sells it for $600. He came over to check out what David had to say about it. Soon they realized that the memory could be made vertical to make it better. All of this was done at home with the memory chip and a soldering machine. While each module cost David $200, he started selling them for $225, still $375 cheaper than the other company. As he noticed that lots of people were buying what he called a “stupid thing” he started raising the price to $300, then to $450 and more each time. As demand got bigger, David got some help from his own son. Sooner or later, it came down to a point where David ended up selling Kingston for $1.9 Billion of US Dollars, not knowing that two years later he will buy it back for $450 Million. His first luck happened when he started selling the memory modules like a crazy man, while his biggest luck came when he just sold his company and bought it back for 4x less than what he sold it for. |

|

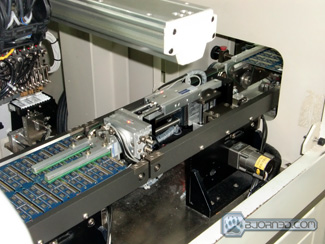

Kingston Hsinchu Factory Tour

During our stay in Taipei, the capital of Taiwan, Kingston not only invited us to their meetings, but also to their factory tour in Hsinchu. We were honored to go, and we did not want to miss the chance to go there while we were in Taiwan. Overall the experience was great, and it will be difficult to duplicate that experience here in the article, but hopefully this will give you a slight overview of how our DRAM, Flash, and other memory modules are made.

We do not have a lot of pictures of Kingston’s Hsinchu factory tour, due to the limited pictures that we were allowed to snap there, but nonetheless, we hope that you will find this short sum-up of the factory tour interesting. We have a more detailed Kingston factory tour of the Fountain Valley’s factory, which is a bit smaller than the one located in Hsinchu, Taiwan. We’d like to invite you to also have a look at the other article of the Fountain Valley’s factory tour HERE.

Unfortunately, there are lot of steps we were not allowed to take pictures of. The way the machines worked would have been a great video opportunity as well, but video recording was not allowed. We hope you have enjoyed this quick overview of the Kingston Hsinchu Factory tour.

Bjorn3D.com Bjorn3d.com – Satisfying Your Daily Tech Cravings Since 1996

Bjorn3D.com Bjorn3d.com – Satisfying Your Daily Tech Cravings Since 1996