We were lucky enough to get a tour of the Kingston Plant in California recently so we thought we’d treat you to an insiders look at their Ram testing and manufacturing plant.

Kingston Factory Tour

We recently were lucky enough to get invited to a Kingston Factory tour in California and we thought that it was rather interesting and would like to share some of the photos and impressions we got while on the tour. Now Kingston has factories all over the globe but this one in California is for the manufacturing and testing of ram so it’s a little more than just chip building machines. They also do compatibility testing across a wide variety of platforms at the plant so there’s actually to much hardware to show you completely.

These type things usually always start off at a Hotel with a meeting, those can be a little lengthy and we’ll spare you most of that but there were a few interesting things to share from the meeting.

Low and behold one of the speakers at the meeting was none other than Fugger who often works with Gigabyte and Kingston at these types of presentations.

Fugger brought out the big guns at this presentation and this is the dual compressor Phase Change unit he was using while OCing the Kingston HyperX he had mounted to the board.

Here’s the P55A-UD6 board he was using to OC the 2GHx kit of HyperX he was using. At the time the P55A-UD6 was unreleased so we were watching him OC the Ram on a virgin platform and he did pretty good for a rookie and got the kit up to around 2400MHz.

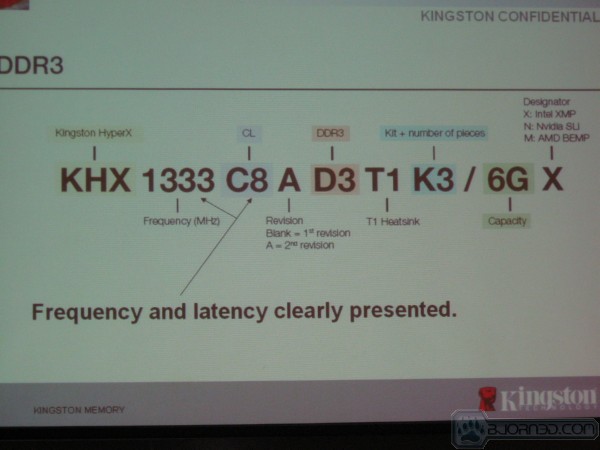

Ever wonder what those cryptic Kingston ram stickers mean?

The First letters are the Rams Designator, here it’s KHX for HyperX, the next 4 numbers are the speed, the next two digits are the Cas Timings of the kit. The A in the center is the revision of the ram kit in this case revision 2 if it’s blank it’s revision 1. The D3 lets you know it’s DDR3 and the T1 is for the heatspreader type, in this case T1 Tall (New) Heatspreader. The K3 tells you the pieces in the kit in this case 3 for a triple channel kit. The 6G is the density of the kit, this one is a 6GB kit and the last letter tells you the platform it’s designed for as far as available profiles.

Sitting around the room were nice hardware displays to drool over. The tall black case had a 4xRaid0 enterprise class SSD array setup and we saw speeds up to 1GB/s from that specific array in selected tests. Just about any test we ran (yes we had hands on) we got speeds ranging from 600MB/s to 900MB/s and we have to tell you it was one sweet setup.

The next rig in the lineup was a Dual SSD rig in a Thermaltake Lan chassis and it was pushing a couple of V series drives in Raid0 which is a lot more affordable than the high end 4xRaid0 (enterprise class) array in the last picture. Just the drives in the last rig would set you back in the neighborhood of $2000. This setup here isn’t nearly as fast but with a couple of 40GB Kingston SSD’s (Intel controller) you could setup a boot drive with 80GB of storage in 2XRaid0 for the neighborhood of $230 and run in the 230MB/s range for read speeds.

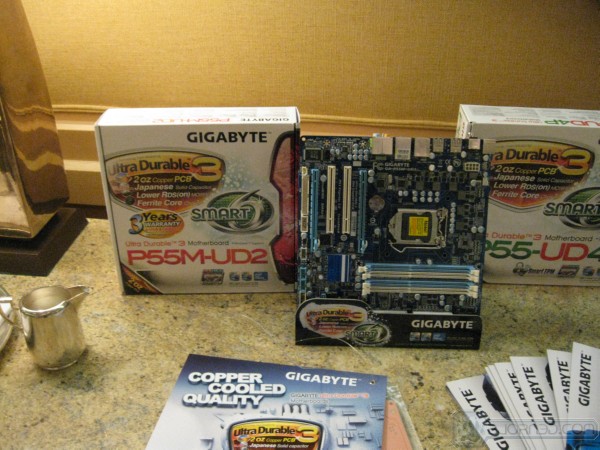

Kingston and Gigabyte have been working closely together to make a great partnership of Gigabyte boards and Kingston ram and we have to tell you that if your going onto a Gigabyte board it might be compatible with a lot of models of ram but with this partnership you’d be silly passing up a kit of HyperX to slap on the Gigabyte board because they run together like a dream. In General HyperX runs like a dream but when the board vendor and Ram vendor partner up you know that you’ll get excellent performance and compatibility.

Most of the boards we saw were early P55 release boards (October meeting) so the P55A-USXX boards weren’t out yet.

Then last in line on that table is the Gigabyte GA-P55-UD6 and we’ve reviewed the P55-UD6 and P55A-UD6 and it’s hard to go wrong with those boards if you happen to be a hardcore performance demanding enthusiast. The 2oz copper PCB helps keep the entire board cool and the 24 phase power with advanced BIOS makes OCing a dream.

When we first walked in the door we thought we had crashed a Gigabyte meeting but then we noticed every machine running Kingston ram and the deer in the oncoming headlights look left our eyes.

We were especially interested in the P55A-UD6 board, we got with Gigabyte at the meeting and insured we would be in on first round testing on the Sata 3 and USB 3.0 board. Turns out we were a little late out of the gate with the 22 page review but unlike a lot of sites we did full Sata 3 and USB 3.0 testing in the boards review.

After an exhausting meeting (and hands on hardware session) we retreated to a really nice resturant and enjoyed the company of the Kingston and Gigabyte gang over dinner. We might get in trouble for telling you this but the Kingston and Gigabyte gang aren’t at all like what most people would imagine. They are polite and professional which you would expect but they are also very friendly down to earth people that we enjoyed meeting and eating with.

We’ll spare you and us the photos of dinner because that’s when everyone lets their guard down and just enjoys the company.

The Factory

Once we had enjoyed dinner with the Kingston and Gigabyte crew we headed back to our Hotel and got a good nights sleep in preparation for the factory tour the next day. It was a fairly uneventful night (lets just say we acquitted ourselves well enough that our names won’t live on in infamy).

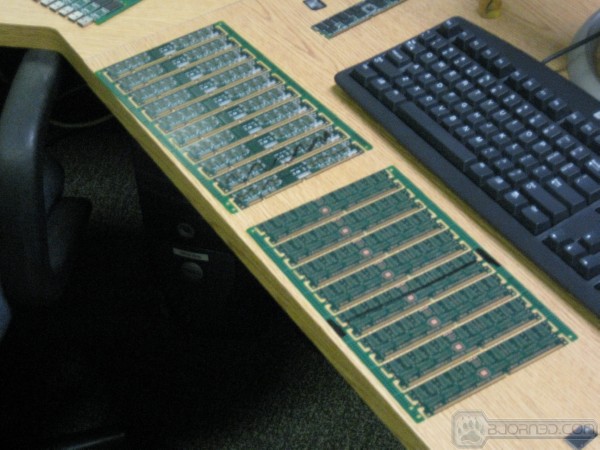

We got into an outer office and were already seeing interesting Ram Blanks and bare product the likes of which the average end user isn’t likely to see. Here’s a couple of pre-production ram blanks before the ram chips and circuitry are installed. Kingston is probably the only vendor that actually designs and cuts it’s own PCB so they have total quality control beginning to end.

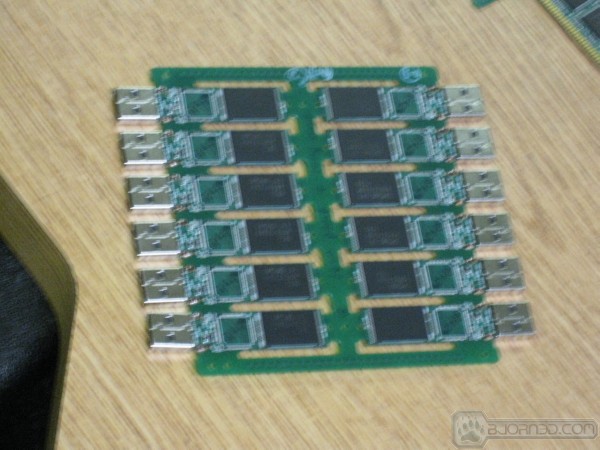

We were faced with difficult factory lighting and the limitation that we couldn’t get shots of any computer screens making pictures challenging but we did get this shot of some naked flash drives before the casing is installed.

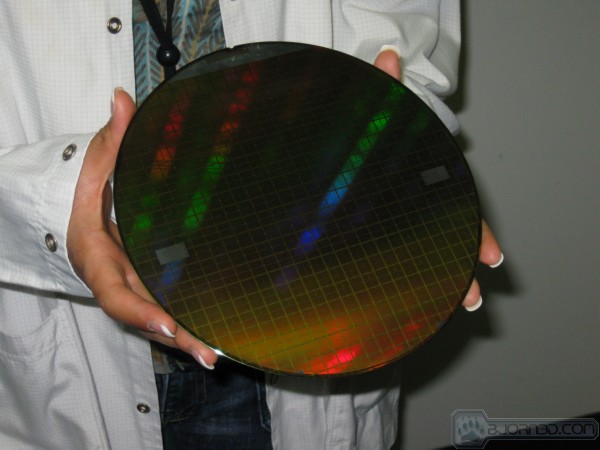

Just laying around the outer office they had a chip wafer in it’s entirety and you can see the individual chips and the cut lines.

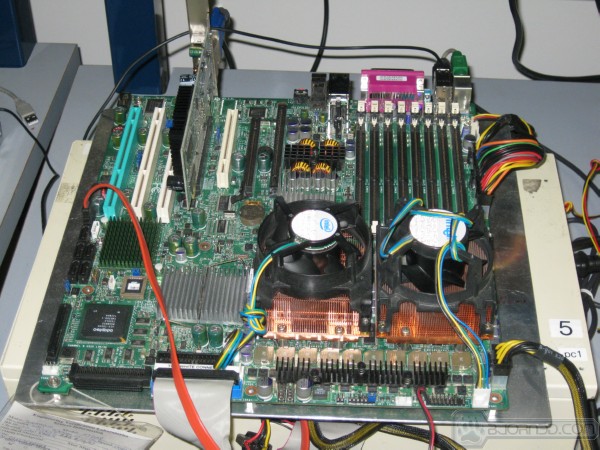

We moved on down the line and ran into some ram compatibility testing labs (several of them) and it was a little amazing the variety of hardware each module is tested on for compatibility. Looks a lot like the Bjorn3D testing lab but on a much larger scale.

How much larger, a lot larger in just one room they had setups for DDR2, SDRAM, DDR1 and behind us DDR3 dual channel. There’s a lot of Blade server and laptop testing going on in this lab.

Here’s a blade with 12 total ram slots, compact power supply and a few output ports on the front. There are more ports on the back but the one thing you won’t find on any blade is a decent Video setup, not even a single PCI-E 16x slot anywhere to be found but you could imagine the fn to be had with 12 ram slots and a sidecar PCI-E 16X slot.

Here’s a shot of different model motherboards on testing stands with a complete blade server in the background.

Here’s a blade sitting next to an older desktop rig you remember when desktops used to actually have the motherboard facing the ceiling and not standing on their side.

It was a little awe inspiring checking out all the equipment in the lab, just imagine a benching lab with that much equipment. All you’d have to do is open the door and toss in a sandwich occasionally and a guy could bench until his eyes fell out of the sockets.

Then low and behold we ran across and older dual socket Intel board that we could remember lusting after. If we had to venture a guess (and we don’t) we’d have to say we just passed through a lab containing about 350K worth of equipment and that’s a conservative guess. More than likely everything we saw was purchased or provided when it was new cutting edge and at the peak of it’s expense cycle.

Factory Tour Cont.

By now you should have started realizing this is a large factory and at this point we have barely scratched the surface. The complex is several buildings spread around a large compound complete with it’s own security force and checkpoints going into the factory area both at the front gate and inside the building. We would have to guess industrial espionage is a factor and we can’t blame Kingston for wanting to protect proprietary designs, we’d hazard a guess that some vendors would chew off an arm to get a tour like we did.

We spotted a blade server earlier and before we move onto the next testing lab we thought we’d toss that shot in for those that have never seen a blade. This is a 9 or 10 blade server depending on the arrangement. Up to 10 complete computers set into slide drawers in one spot all capable of independently or cooperatively processing data or tasks. Pretty impressive but these are more for data and server farm environments and lack the amenities hardcore enthusiasts demand. Still that’s a lot of computing punch in a decently small package.

By this time we’d wandered past several hundred bare bone computers of different makes and models the Kingston uses to test compatibility with and we were getting a little desensitized to massive rows of rigs begging for hands to play with them.

A lot of the rigs we saw were actually idle or turned off but there was active compatibility testing going on while we were wandering through.

We wandered out of the lab and David (our Kingston PR contact) showed us the American support senter for Kingston. Imagine that a support center inside the USA where you can talk to a live human whose first language is actually English. (Ever heard this one, “I zam ze techyitittion ewe mus lisen to meee”, I think we’ve all talked to that guy.) That isn’t the case here at Kingston’s California support section, we actually saw calls come in and the efficient manner in which they handled them.

Here’s a little more of the staff working hard to keep Kingston’s machine up and running. During the tour they mentioned that Kingston must accuire up to 25 million individual components daily just to stay in operation. How would you like to be that section? Boss: “well you’ve let me down today you only pulled in 22 Million parts so we have to send 30 people home today.” Employees, “Send me send me.” (Joke)

We did spot a closed lab where we suspect they had highly confidential material like that suspicious brown bottle with the glass cork.

Here’s a shot of part of the factory floor where quality control testing goes on. Every single Kingston Module is 100% fully tested and passes quality control testing prior to leaving the factory. We didn’t talk about it specifically but somewhere in the maze of workstations they test RMA products but we suspect that those people are a little like the Maytag man. We’ve had RAM kits fail over the years but I’ve never had a Kingston kit fail on me in 20+ years. I’ve got a few kingston kits that have been in operation on and off for almost that long. While other kits come and go I seldom let go of my Kingston because of it’s reliability and longevity.

Getting ready to move into the manufacturing area we saw a couple of racks of naked ram that has finished the manufacturing process but hasn’t gotten it’s heatspreaders yet. We thought we had a pile of ram but Kingstom makes our pile look slim.

The Factory Cont.

Well we’ve been past lab after lab of compatibility testing, Support desks and ventured into the fabrication section of the factory. Now we realize it’s a little silly but when you think of factories you think of scores of workers running around in a highly coordinated dance like worker bee’s gathering and storing pollen. It’s not like that in most computer related factories we’ve seen. A lot of the computer industry is automated for quality control purposes. The days of hand placing components in large clumsy PCB’s has long past.

Kingston uses a highly efficient straight line manufacturing process. From where we are standing the chip PCB blanks come into the manufacturing process with no chips on the PCB’s but the data paths have been etched on the PCB’s and the data lines have been installed in the etched paths.

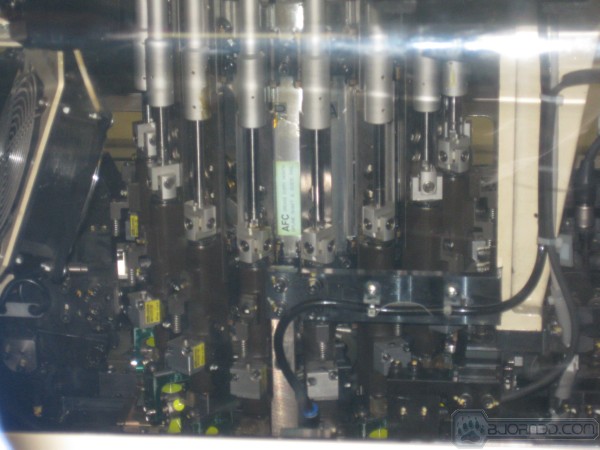

As the PCB’s move down the line a robotic machine places chips in the open holes ready to receive them. Notice the red, yellow and Green lights on the machines. That’s part of the automatic quality control during manufacturing, if a part has a problem a red light flashes to let the attendant know but for the most part manufacturing anomalies are handled by the machines themselves.

Forgive us but here again we are dealing with factory lighting and reflective/protective surfaces on working machinery. Ram was being manufactured as we strolled through. As the ram passes through each section of the straight line manufacturing process each machine does it’s part checking and aligning the chips prior to sending them to the soldering station.

It was hard to get a shot of the machine without blurring it because the robotic arms move so fast you know they are placing chips but it’s happening so fast your eyes can’t see individual operations.

Here PCB blanks have chips on them and are moving down the line. This particular set some of the PCB’s didn’t get chips so for whatever reasons the previous machine rejected the PCB’s as viable.

Then the chips move on to the next process before going into the closed oven to bake the solder in. Kingston uses a cold soldering process where the solder is already on the PCB prior to coming into the manufacturing section, machines place chips on the PCB blanks, check alignment, then send them down the line to an oven where the chips are heated and the solder melts and makes the connections.

Once we got past the automated section we were running low on time (Early flight home) so we headed back out onto the floor to look at ram testing at it’s finest.

See that large machine down at the end, the one with the orange in front of it. That’s an automated testing machine that will knock your socks off.

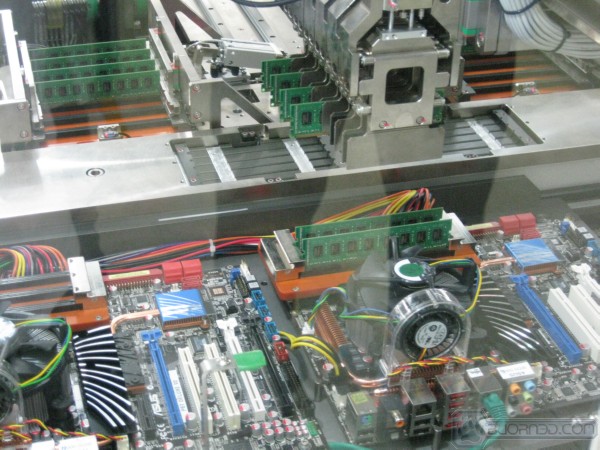

Inside the machine is dozens of motherboards slightly modified so the machine can insert and test ram without human intervention.

All the boards rotate from top to bottom on a large board transportation system that would make a Transformer jealous, You almost expect the machine to unfold stand up and say something to you it’s got that many moving parts.

The testing rig has a bank of ram chips waiting on boards to pass by and an arm will pick up a predetermined amount of ram and have it ready to slam in a board,

Here you can see the arm with 4 chips ready to insert them into the boards.

Then just before I dashed out the door to a waiting cabby I got to see the boards after ram had been inserted moving through the testing rig.

Conclusion

Throughout our tour we were impressed with the professionalism of the Kingston staff, the manufacturing process, and the sheer amount of equipment in one factory. Then you have to know that there are several of these facilities scattered around and this one isn’t even the largest. This facility is geared more for smaller specialty runs of ram than mass production of large numbers of mainstream kits but still it is a little like Jonah entering the proverbial whales belly.

Every step of the way from the security checkpoint at the front of the factory to the outer offices everything we saw was a model of efficiency and quality control. Machines track flaws, people track machines, and each and every stick of ram passes quality control with 100% testing prior to leaving the factory.

While Kingston is international in nature they have a factory on American soil and that by itself is impressive. There are places where manufacturing can be done with less expense but they put a plant in the USA bringing not only great ram but also jobs.

We also discovered a dying creature, native English support personnel. While we couldn’t build a ram stick if our lives depended on it we come away with a greater appreciation for ram manufacturing in general and a true respect for Kingston’s state of the art manufacturing and quality control.

Bjorn3D.com Bjorn3d.com – Satisfying Your Daily Tech Cravings Since 1996

Bjorn3D.com Bjorn3d.com – Satisfying Your Daily Tech Cravings Since 1996